F3SG-SR / PG Series

Safety Light Curtain/Safety Multi-Light Beam

Easy to monitor and ready for IoT

last update: May 12, 2025

This series redefines safety at manufacturing sites

Manufacturers now need to manage globalization and flexible production.

That's why we have developed our F3SG-SR/PG Series.

This series offers a complete lineup of light curtains that comply with global safety standards and a wide range of functionality that covers all aspects from design through to maintenance.

The F3SG-SR/PG Series helps manufacturers build safety systems.

Design -Easy design of line safety-

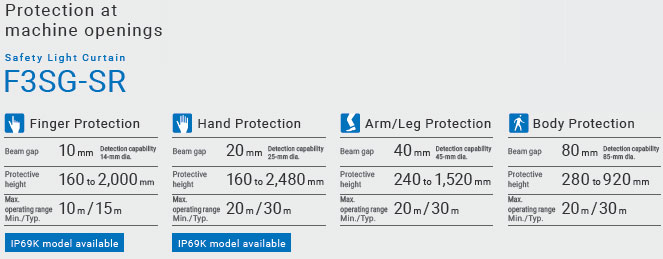

One series covers all protection applications—from machine openings to perimeters of equipment

Standardize mechanical design across production lines and eliminate complexity of selection and design.

Common accessories including cables and brackets *

The light curtains share common accessories for ease of design and retrofit ting of production lines.

Helps build safety systems for machines all over the world

Design -Flexible design for equipment-

A broad lineup for flexible production line design

Create flexible design plans to suit your equipment requirements.

Long operating range thanks to unique optical design

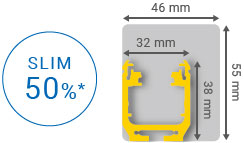

Omron’s unique compact design

This makes mechanical design more flexible.

* Compared with OMRON Robotics and Safety Technologies, Inc’s PA46 Perimeter Access Guarding Device. (Based on

Omron investigation in June 2018)

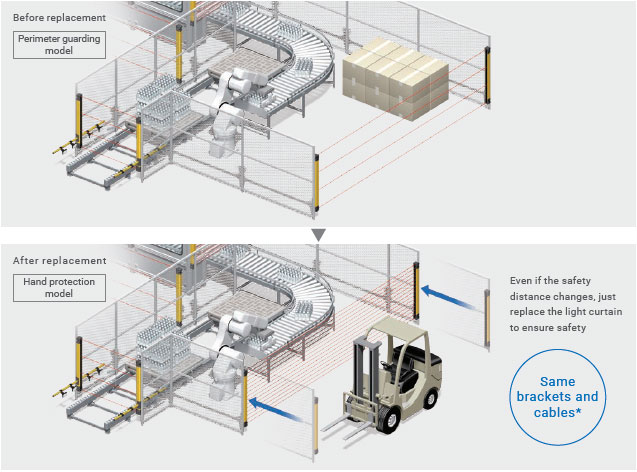

Easy line layout changes

Example: In order to install the light curtain closer to the machine, the perimeter guarding model is replaced

with the hand protection model.

Just replace the light curtain with the same protective height*

Flexible installation

Perfect fit

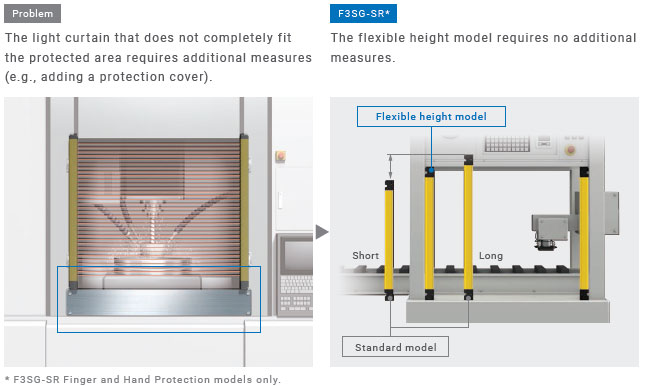

Protective heights are available in increments of 40 mm up to 1,000 mm*. The perfect protective height for any protected area ensures safety without the need for additional measures.

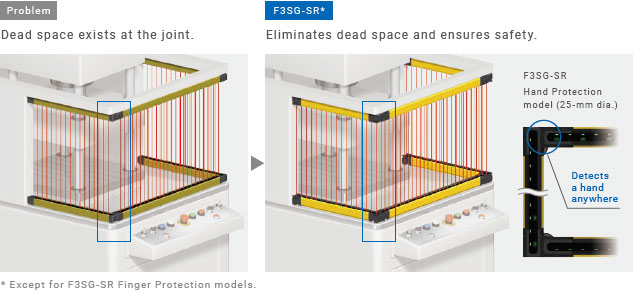

Protection without dead space

The F3SG-SR Series eliminates dead space that previously existed even when light curtains are series-connected or U-shape connected. Safer systems can be designed.

Simple wiring for flexible design

The F3SG-PG-C Perimeter Guarding Passive Mirror requires wiring of only the emitter/receiver.

The use of an optional mirror column allows wiring at one location for protection around perimeters of equipment. They reduce wiring duct design and wiring time.

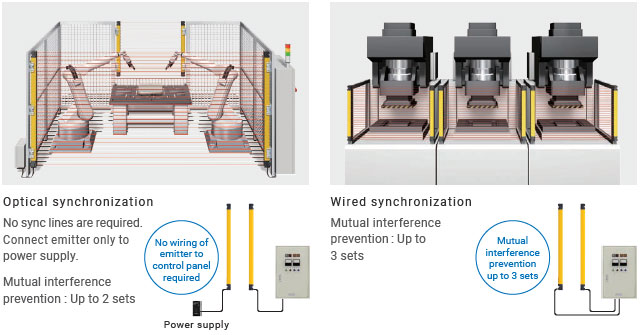

Two different synchronization methods

Choose from two different methods of synchronization between the emitter and receiver to suit your equipment .

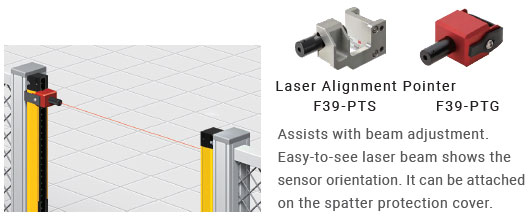

Set-up -Simple beam adjustment-

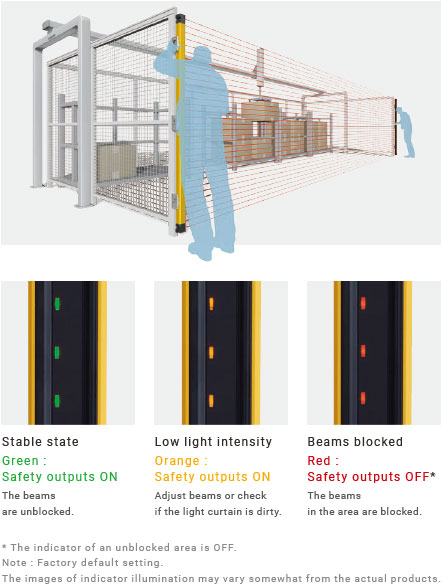

Color indication of beam status for quick and easy beam adjustment

Reduce beam adjustment time.

Area Beam Indicator (ABI) for an at-a-glance check of beam status [PATENTED]

The ON or OFF state of the light curtain and low light intensity can be checked.

The ABI also facilitates fine adjustment of beams for long-distance sensing.

Set-up -Easy installation and angle adjustment-

A variety of optional accessories for easy installation and angle adjustment

Reduce installation time and easily adjust beams after installation without relying on the expertise of experienced engineers.

Easy beam adjustment after installation

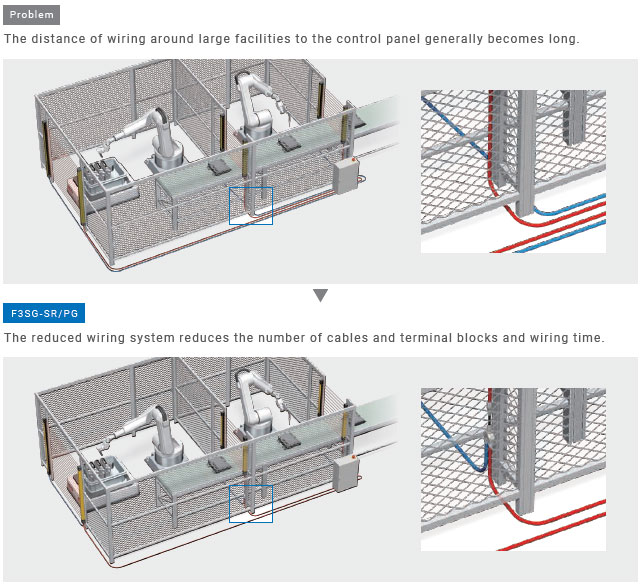

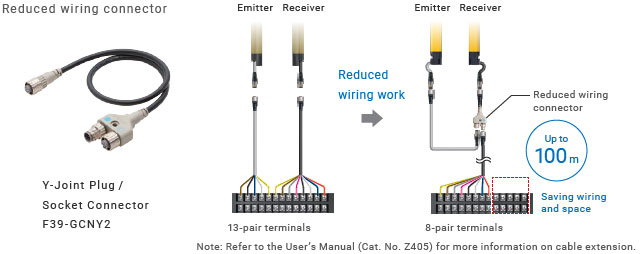

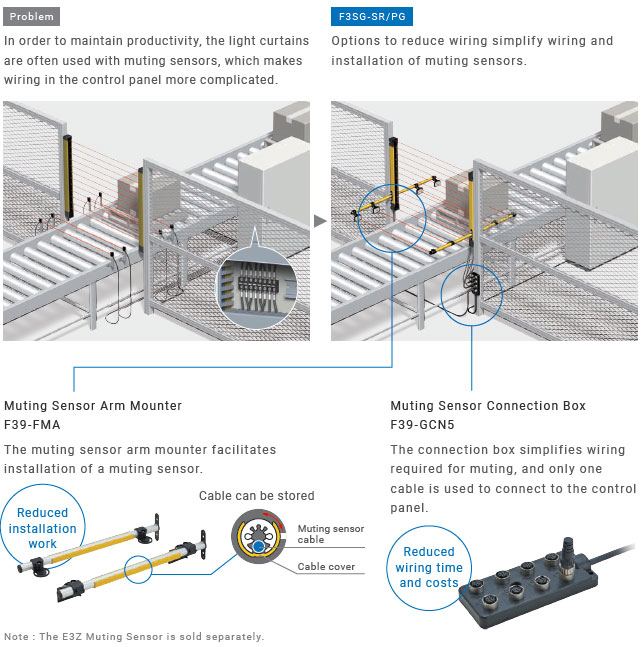

Set-up -Various options to reduce wiring-

Reduced wiring system for various equipment

Wiring work during line installation and maintenance can be greatly reduced.

Simple wiring around large equipment

One cable connection to control panel

Options provide simple wiring for muting.

Operation -Reduction in unwanted machine stoppages-

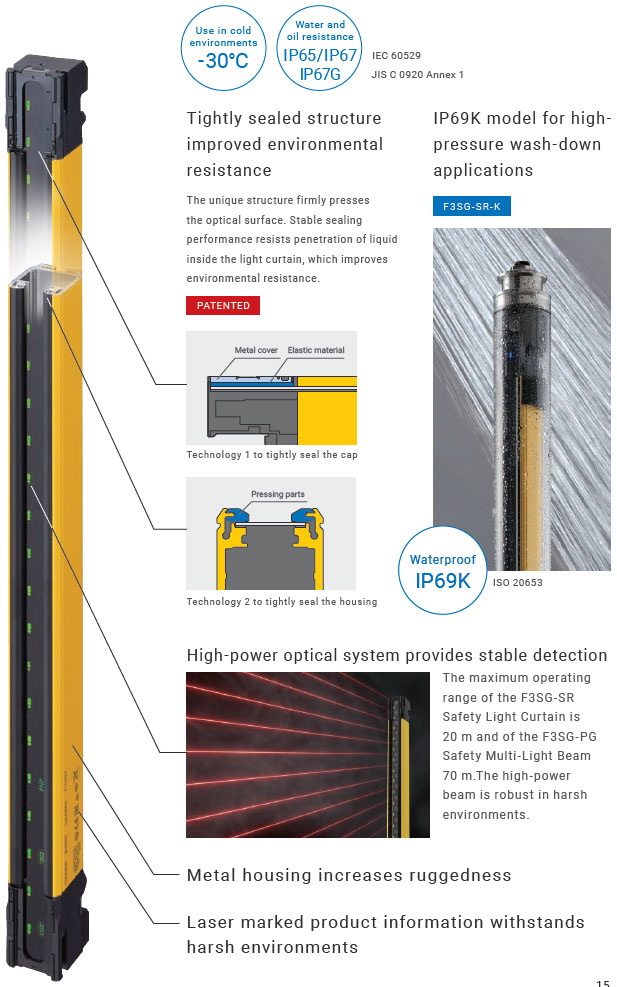

Robustness for operation in harsh environments

Specifications suitable for use in any environment contribute to stable operation.

Designed for reliable use in harsh environments where light curtains are prone to malfunction

Maintenance -Maintenance with no special skills required-

Easy maintenance

Even inexperienced operators can easily check status and replace light curtains.

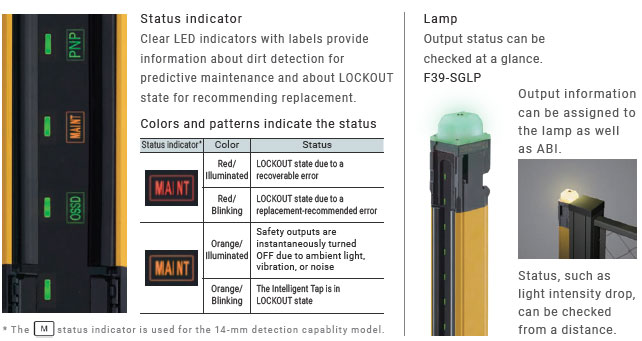

Easy error diagnosis with clear color indicators

The light curtain status can be checked at a glance.

For information on other indicators, refer to the F3SG-SR/PG Datasheet (Cat. No. F117) Indicator or Troubleshooting.

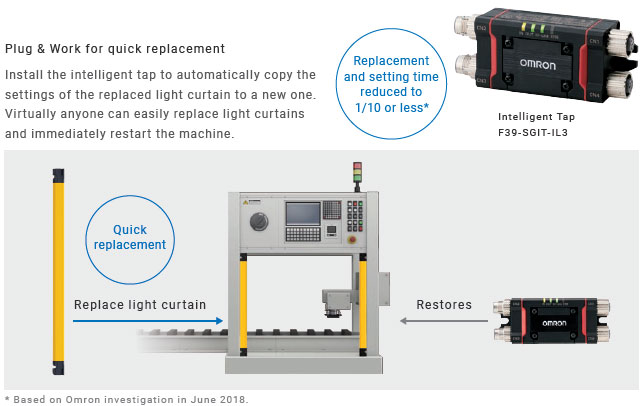

Back up and restore set tings with intelligent tap

Replacement and set ting time during maintenance can be reduce d to 1/10 or less*.

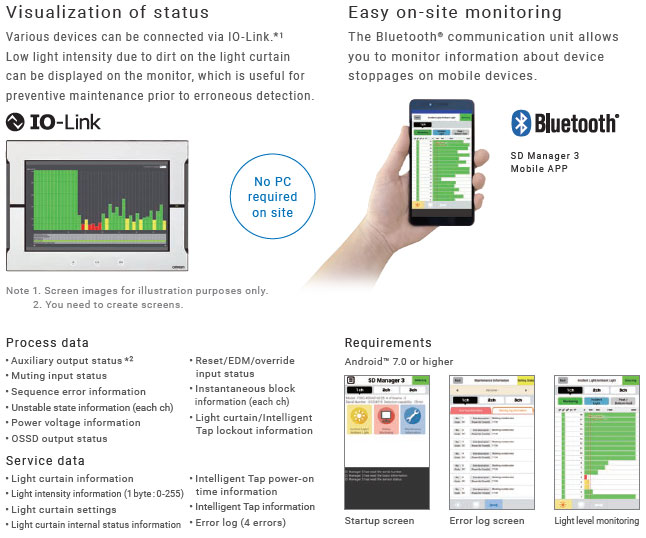

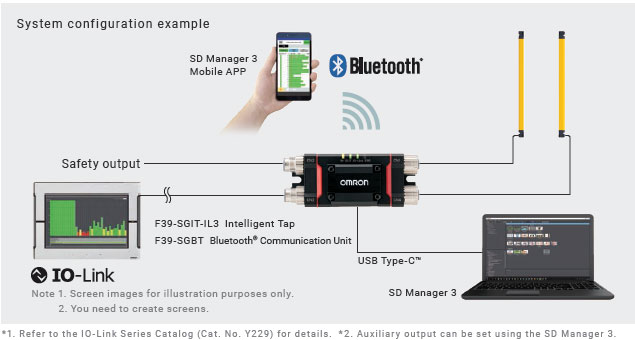

Maintenance -Quick maintenance through ICT-

Preventive maintenance

The status of the light curtain is monitored, and the abnormal state is displayed.

This helps minimize machine downtime.

last update: May 12, 2025